|

[

BACK ]

[

TOC ] [

NEXT ]

6 VOLT ELECTRICAL SYSTEM

The Six volt electrical system includes the Storage

Battery, Generator, Generator Regulator, Starting Motor, Ignition Coil,

Distributor, Spark Plugs, together with the necessary cables.

|

|

Distributor |

|

| |

Model

|

1BB-4101-M |

| |

Cam Angle

(Dwell) |

27 1/2°

to 30° one set of points

34° to 36° Total Dwell |

| |

Gap

|

.015" to

.018" |

| |

Breaker Arm

Tension |

17 to 20

ozs. |

| |

Condenser

Capacity |

.250 to

.285 MFD. |

| |

Timing Mark

Location |

Vibration

Damper |

| |

Rotation

|

Clockwise |

| |

Firing

Order |

1-8-4-3-6-5-7-2 |

| |

Automatic

Advance Curve |

400 R.P.M.

0-1° -- 650 R.P.M. 1-3°

1025 R.P.M. 4-6° --

1400 R.P.M. 7-9°

1775 R.P.M, 10-12° |

| |

|

|

| |

Ignition

Coil |

|

| |

Model |

CR6015 |

| |

Ampere Draw |

|

| |

Engine

Idling |

2.25 AMPS |

| |

Engine

Stopped |

5. 0 AMPS |

| |

|

|

| |

Starting

Motor |

|

| |

Model

|

M C L 6201M |

| |

Voltage

|

6 |

| |

Number of

Brushes |

4 |

| |

Spring

Tension |

42 to 53

oz. |

| |

Field Coils |

4 |

| |

Drive

|

Bendix type

Folo-Thru |

| |

|

|

| |

Free Run

Test |

|

| |

Voltage

|

6 |

| |

Ampere Draw |

50 to 65 |

| |

RPM

|

5300

|

| |

|

|

| |

Stall

Torque Test |

|

| |

Torque

(Foot Pounds) |

8.0 LBS. |

| |

Voltage

|

2.0 |

| |

Amperage

Draw |

410 |

| |

|

|

| |

Generator Regulator |

|

| |

Model

|

VAV 6001

B12F |

| |

Ground

Polarity |

Positive

|

| |

|

|

| |

Cut-Out

Relay |

|

| |

Armature

Air Gap |

.031 to

.034 |

| |

Contact

Point Gap |

.015 |

| |

Closing

Voltage |

6.4 to 7.0 |

| |

Opening

Voltage |

4.1 to 4.8 |

| |

|

|

| |

Voltage

Regulator |

|

| |

Armature

Air Gap |

.048 to

.052 |

| |

Operating

Voltage |

7.2 to 7.5 |

| |

|

|

| |

Current

Regulator |

|

| |

Armature

Air Gap |

.048 to

.052 |

| |

Operating

Amperage |

50

|

| |

|

|

| |

Generator |

|

| |

Model |

GGU 6001-R |

| |

Type

|

6 Volt

Shunt Wound |

| |

No. of

Brushes |

Two |

| |

Field Coil

Draw |

1.7 to 1.8

at 6.V |

| |

Motoring

Draw |

5.5 to 6.5

at 6.V |

| |

|

|

| |

Hot

Output |

|

| |

Volts |

8 |

| |

Max Amp |

50

|

| |

Max R. P.

M. |

1840

|

| |

|

|

| |

Battery |

|

| |

Model |

MW-2-135R |

| |

Voltage |

6 |

| |

No. of

Plates |

19 per cell |

| |

Capacity

|

135 Amp.

hrs. |

| |

Terminal to

Ground |

Positive |

| |

|

|

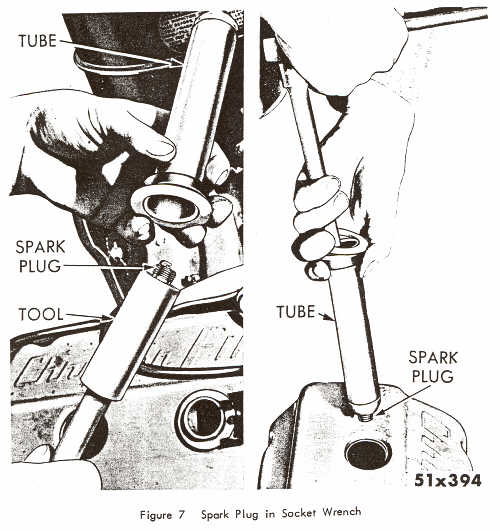

SPARK PLUGS

Spark plugs used in the Siren Engine are the resistor

type (4S165), size 14mm. After cleaning the Spark Plugs, adjust the gap

to .035 inch, using a round wire feeler gauge. Make all adjustments on

the side electrode of the Spark Plug. If center electrode is bent, the

porcelain may crack, resulting in plug failure. Do not drop Spark Plugs

into the tubes as this may cause the gaps to close up. When installing,

place a Spark Plug in the socket wrench (Figure 7) and bring the tube

down over the Plug. Hold the Plug down in the tube and insert the

assembly into the Cylinder Head. Tighten Spark Plugs using a torque

wrench thirty (30) to thirty-two (32) foot pounds.

[

BACK ] [

NEXT ]

|